Vibration Control Engineering Services

High vibration levels can hurt both structures and humans. We'll help you predict and solve machinery vibration problems before they occur through advanced vibro-acoustical measurements and computer simulation techniques.

Ask our experts

What Causes High Vibration Levels?

The majority of machinery in manufacturing processes employ vibrating or rotating principles to perform their operating role within the plant. Industrial equipment such as vibrating screens, vibrating feeders, crushers, grinders and vibratory centrifuges are good examples. For such equipment, high vibration levels from the operating process is likely to be transmitted to the supporting structure or adjacent machinery.

Vibratory resonance is the main cause for large vibration levels and it could lead to significant damage or even failure of the equipment and supporting structures. Additionally, such resonance condition causes increased noise levels leading to considerable human discomfort.

Solving Your Vibration Problems

Soft dB collaborates with your team of structural, mechanical or aerospace engineers to assist in the vibrational and dynamical analysis to find the most appropriate solutions to their vibration issues.

Our experts combine state-of-the-art vibration measurements and computational techniques to provide unique vibrational and acoustics consulting services that cover all aspects of the field of vibration, from practical mitigation solutions to engineering support during the design stages.

Applications

Vibrating Screens

Centrifuges

Crushers

Turbines

HVAC Systems

Vibration Control and Mitigation

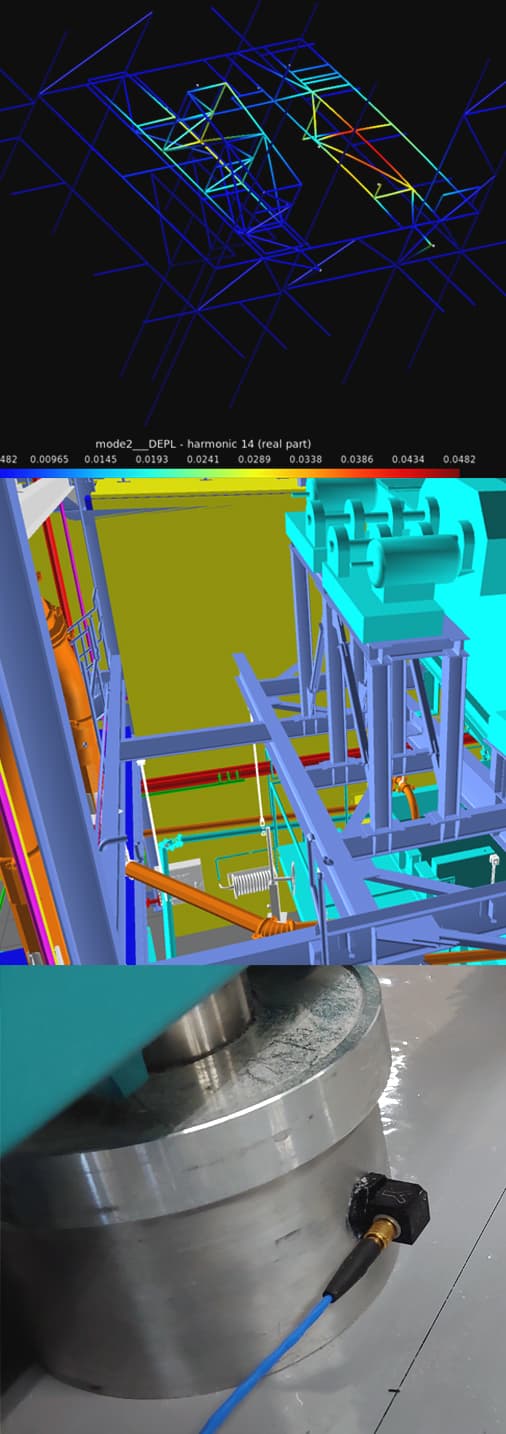

An accurate vibration analysis is the first step to reducing high vibration levels affecting a system. If the vibration problem affects an existing machine or structure, a measurement campaign is first conducted in order to determine the vibrational state of the system. A vibration analysis of the measurements will highlight the correct path towards an appropriate solution.

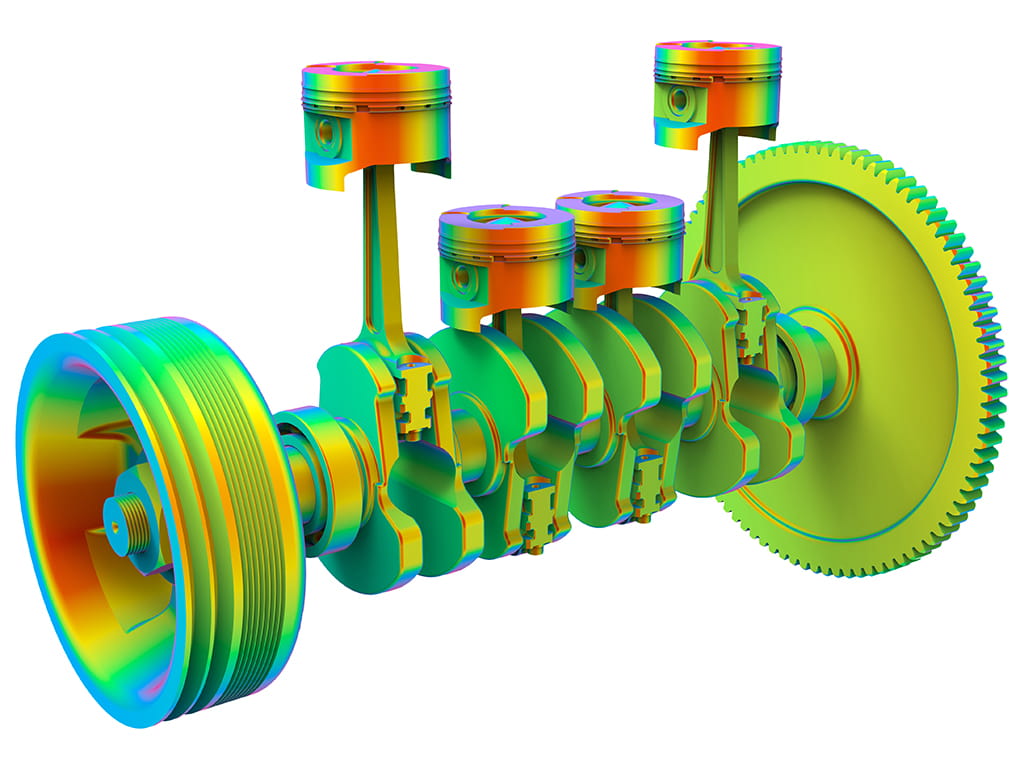

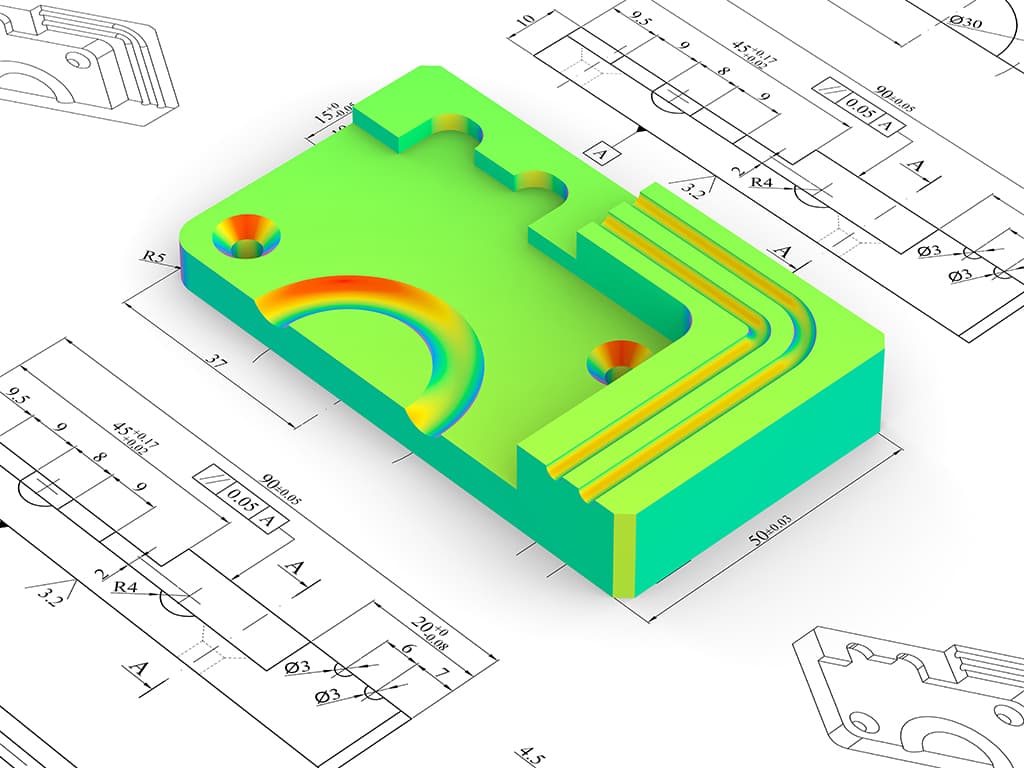

Advanced computational techniques, such as Finite Element Methods, are then required to compute the resonance condition and the dynamical system’s response due to the excitation source. This type of computation provides a detailed characterization of the vibrational and dynamical behavior in order to identify vibrational issues and propose efficient mitigation solutions.

Product Design Consulting

During the design phases of product development, engineers need guidance on the vibration levels of their future product in order to comply with regulations while meeting customer expectations. Engineers also need to investigate and optimize the performances of different designs to achieve their target. Prototyping and experiments can be used to estimate vibration levels in your design. However, in large-scale systems, this approach can be costly and in the worst cases can be impossible to build it. In such cases, advanced computational techniques, such as Finite Element Methods, not only provide an accurate assessment of vibration levels, but also allow the exploration of solutions that may not have been accessible through experiments.

Vibration and Dynamic Finite Element Analysis

To reduce the high vibration levels affecting your system or to estimate the vibrational characteristics of your designs, Soft dB offers a unique set of advanced simulation services using Finite Elements Analysis. Based on the vibration problem, different types of analysis are required:

Modal Analysis of Linear and Nonlinear Systems

- Calculation of resonance conditions: natural frequencies and modes of vibration

- Characterization of advanced vibrational properties: modal mass, stiffness and damping

Time History Analysis

- Investigation of transient and steady-state dynamics as a function of time

- Simulation of stress waves due to impact, pile driving, earthquakes, etc.

Harmonic Analysis

- Computation of the frequency response function (FRF) and transfer function

- Estimation of experimental damping ratio achieved through field measurements

Nonlinear Transient Dynamics

- Simulation of complex phenomena: fluid-structure interaction, vibro-impact behavior, nonlinear materials, nonlinear boundary conditions, etc.

- Computation of nonlinear resonance conditions: backbone curves and modes of vibration

Fatigue Analysis

- Estimation of the total life of a system subject to cyclic loading

- Prediction of crack development in mechanical designs

Random Vibration Analysis

- Simulation of dynamical behavior of systems subject to random vibration patterns

- Computation of vibrational characteristics of systems subject to earthquake

Acoustics and Vibro-Acoustics Simulations

- Prediction of sound and vibration levels through the state-of-the-art combination of vibration and acoustics computational models

- Computation of mitigation measures to reduce high noise levels

Don't Let High Vibration Levels Affect Your Equipment and Workers

Reducing high vibration levels affecting your operations starts with our unique expertise. No vibration problem is too small or too complex for our world-class team of engineers.

Ask our experts